Low Core Loss Amorphous E-Core

Product Image

Meet the “Strong Heart” of Your Power Electronics.

It is not just a block of metal; it is a precision-engineered highway for magnetic flux.

This core is designed to replace traditional ferrite and silicon steel with superior efficiency.

Whether you require the cost-effectiveness of Amorphous alloy , we customize the core to your exact needs.

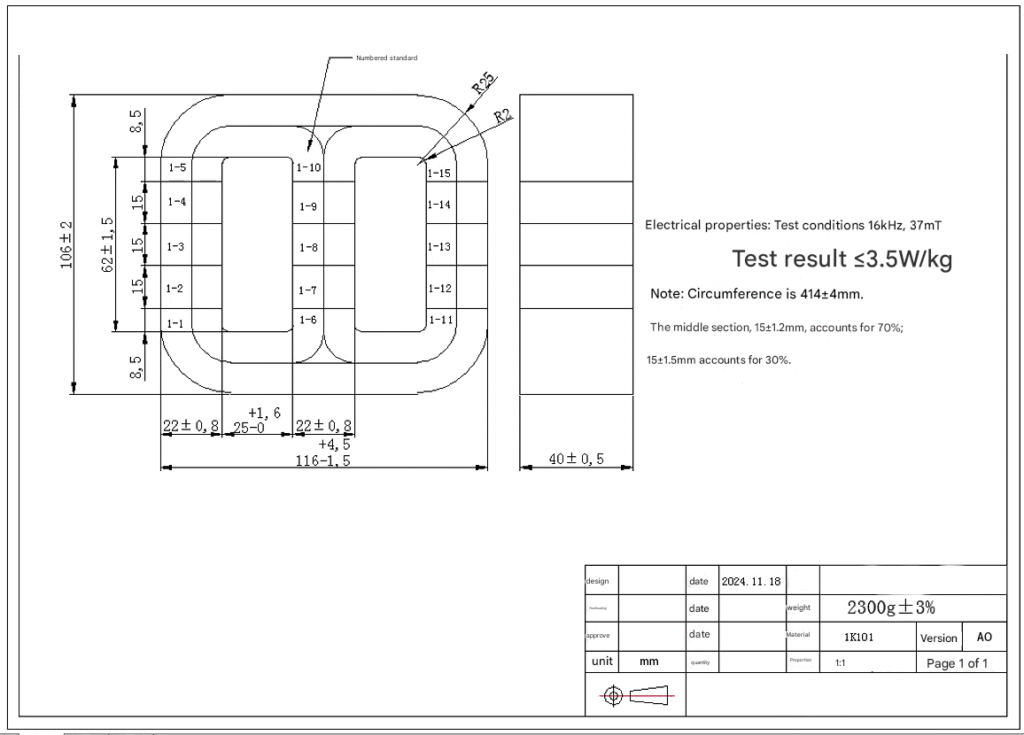

With a core loss of ≤3.5W/kg(at 16kHz), the core ensures your transformers stay cool, quiet, and incredibly efficient. Stop wasting energy on heat and start maximizing performance.

We strictly adhere to international standards, ensuring that every core—from the 1st to the 10,000th—fits your engineering drawings perfectly.

Key Features

Efficient at mid-/high-frequencies for lower temperature rise.

Protective coating

Dual Material Mastery: Available in both Fe-based Amorphous (for robust power handling) and Nanocrystalline options.

Ultra-Low Core Loss: Tested at 16kHz / 37mT with losses ≤3.5W/kg. This means higher efficiency and lower operating temperatures for your devices.

Precision Engineering: Manufactured with strict dimensional tolerances (see specs below). The 414±4414±4mm perimeter is controlled to ensure consistent magnetic path length.

High Saturation Flux Density: Designed to handle high currents without saturation, making it ideal for compact, high-power designs.

Versatile Structure: Available as a C-Core (cut core) or Toroidal (uncut), with precision air-gap adjustments available upon request.

Applications

- High-Frequency Power Transformers: For welding machines, X-ray power supplies, and laser power supplies.

- Solar Inverters (PV): Boost reactors and output filter inductors.

- Electric Vehicle (EV) Chargers: On-board chargers and DC-DC converters.

- UPS Systems: Uninterruptible Power Supplies requiring high reliability.

- Induction Heating: Equipment requiring stable magnetic performance at high frequencies.

Key Specifications

| Core Material | Fe-based Amorphous alloy |

| Effective Permeability μe | Custom per gap: typical 500–20,000; tighter ranges available on request |

| Ungapped μr (reference) | 5,000–20,000 (material), tuned via heat treatment |

| Saturation Flux Density Bs (typ.) | ≈ 1.56 T |

| Ribbon Thickness | 18–25 µm standard (14–35 µm optional) |

| Operating Temperature | −40–150 °C (consult for higher ranges) |

| Forms | Split toroid, C-core, E-Core; coated or cased versions |

| Compliance | RoHS / REACH friendly |

Values shown are typical engineering ranges; final datasheets and drawings prevail for ordering.

Typical Applications

PFC / Energy Storage Chokes

Server PSUs, chargers, industrial drives

EMI Filters

Common-mode & differential-mode inductors

PV / ESS / UPS Inverters

DC-Link and LCL filtering

On-board Chargers & DC Fast Charging

High power density with low loss

Welding / Induction Heating

High-frequency, high-current environments

FAQ

Why choose an amorphous E cores?

Choose Amorphous E cores for their superior efficiency and power density. With a high saturation flux density of 1.56T—three times that of ferrite—they allow for significantly smaller and lighter designs (often reducing weight by up to 50%). Their unique non-crystalline structure results in extremely low core losses, minimizing heat generation and boosting system efficiency compared to silicon steel. This makes them the ideal choice for high-power applications like solar inverters, UPS systems, and EV chargers, offering a perfect balance of high performance and compact size.

How does it compare with ferrite?

Amorphous cores feature a Saturation Flux Density (Bs) of 1.56T—three /five times that of Ferrite(0.3~0.5). This allows for 50% smaller and lighter designs with far superior thermal stability, making them ideal for high-power density applications.

How does it compare with Silicon Steel?

Amorphous cores deliver 70% lower core losses compared to Silicon Steel. While Silicon Steel is limited to low frequencies (50/60Hz), Amorphous E cores operate efficiently at higher frequencies (up to 10kHz), providing superior efficiency and significantly reduced heat generation.

Do you support non-standard sizes and colors?

Yes. We can customize size, permeability target, various shape (toridal / Rect. / Oval / Cut) to match your specifications.

Need a quick recommendation or sample?

Share your inductance, frequency, current, size limits, and thermal targets. We will propose core grade, geometry, and turns with a loss/temperature estimate.